As Per Market Research Future, the Tool Steel Market Growth is driven by the increasing demand for efficient and durable tooling solutions in response to the rising industrial production. The growth of this market is supported by several factors, including advancements in tool steel technology, the rising adoption of high-strength alloys, and the growing emphasis on sustainability in manufacturing processes. Innovations in industrial tooling materials and the demand for wear-resistant steel grades are also contributing to market growth. As industries prioritize quality and performance, the tool steel market is expected to witness sustained growth.

The Tool Steel Market plays a crucial role in industrial manufacturing, offering high-performance materials for cutting, shaping, and molding applications. Tool steel is widely used in automotive, aerospace, and construction sectors due to its durability, hardness, and resistance to wear and heat. Increasing industrialization and demand for precision-engineered components have fueled the growth of this market globally.

Market Overview

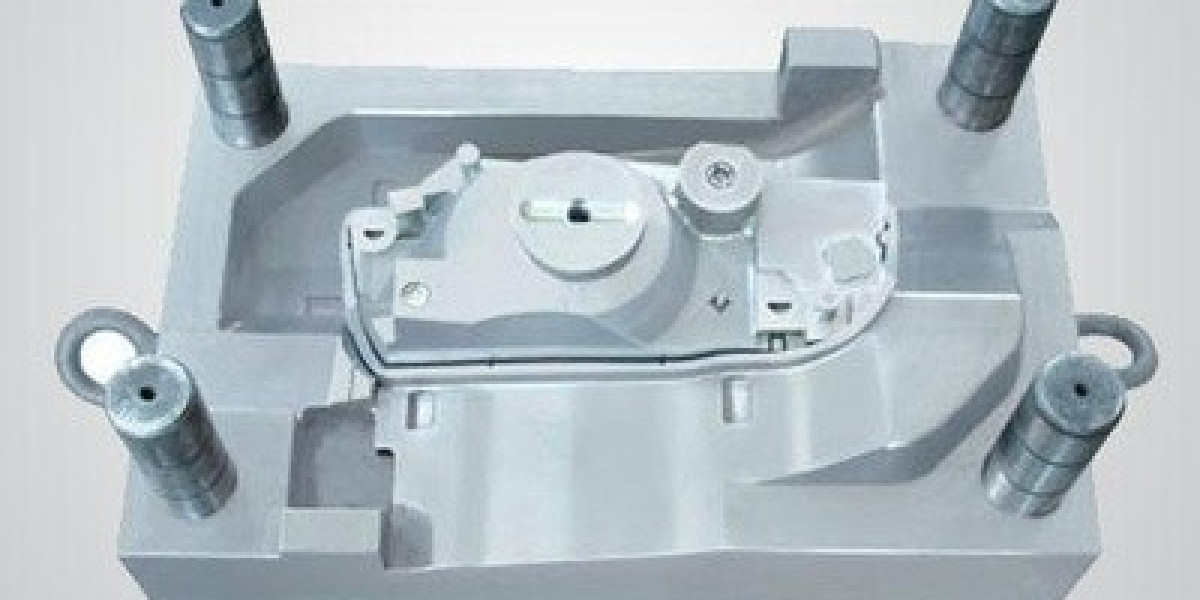

Tool steel refers to a category of carbon and alloy steels optimized for tool manufacturing. These steels are designed to withstand high pressures, extreme temperatures, and repeated wear, making them ideal for producing dies, molds, and cutting tools. Market growth is closely linked to the expansion of manufacturing industries and technological advancements in material science.

Market Drivers

The demand for high-quality and durable materials drives the tool steel market. The automotive industry, in particular, requires robust components for engine parts, dies, and precision tools. Industrial automation and CNC machining have increased the need for advanced tool steel varieties that offer strength, hardness, and thermal stability. Furthermore, research and development in alloy compositions have enhanced tool steel performance, creating opportunities for market growth.

Product Segmentation

Tool steel is categorized based on its manufacturing process and application. Common types include water-hardening, air-hardening, shock-resistant, high-speed, and die steel. Each type has specific characteristics suitable for different industrial processes. Water-hardening and air-hardening steels are popular for their ease of use, while high-speed steels are preferred for cutting and machining operations requiring high efficiency and precision.

Regional Insights

Asia Pacific dominates the tool steel market due to the presence of large manufacturing hubs in China, Japan, and India. Europe is a significant market with established automotive and industrial machinery sectors. North America benefits from technological advancements in metal processing and strong demand in the aerospace and automotive industries. Emerging regions in Latin America and the Middle East are witnessing gradual growth, driven by infrastructure projects and industrialization.

Competitive Landscape

The tool steel market is competitive, with major global players investing in innovative alloys and sustainable production processes. Companies focus on product differentiation, quality enhancement, and expansion of distribution networks. Strategic alliances, joint ventures, and technology upgrades are key strategies to maintain a competitive edge. Brand recognition, consistent product performance, and industry certifications are essential for gaining market trust.

Future Outlook

The tool steel market is expected to expand further with increasing industrialization and demand for high-performance materials. Growth in automation, adoption of advanced manufacturing technologies, and innovations in steel alloys will drive the market. Companies emphasizing research, product quality, and eco-friendly manufacturing practices are likely to emerge as industry leaders in the coming years.

FAQs

1. What industries use tool steel extensively?

Tool steel is widely used in automotive, aerospace, construction, die-making, and manufacturing industries requiring high-strength and wear-resistant materials.

2. What are the main types of tool steel?

Water-hardening, air-hardening, shock-resistant, high-speed, and die steel are the main types of tool steel used in various applications.

3. Which region dominates the tool steel market?

Asia Pacific leads the market due to large-scale industrial production and significant demand from automotive and manufacturing sectors.

More Related Reports:

Ac Servo Motors And Drives Market

Air Compressor Controller Market